3D Manufacturing: Promises, Pitfalls and Potential

21 October 2013

For as long as they have been around, 3D printers have been heralded as a revolutionary technology and have been described as a path to a new economy, or the route to a new method of distributed, decentralized and domesticated manufacturing. As is often the way with new technologies, many of these predictions and utopian and dystopian visions have not come to fruition. As the hype surrounding printed, computer-aided, digital objects begins to stir again, the Institute of Making invited materials, technology and design experts and enthusiasts to revisit 3D manufacturing for a day of discussion, exploration, experimentation and sharing of expertise.

This workshop gathered together researchers from architectural, fine art, biomedical, chemical, engineering, computer science, museological and anthropological backgrounds for a discussion, demonstration and making session.

Guests arrived to find a variety of printers and innovative examples of printed objects - ceramics, conductive plastics and gel bioscaffolds - dotted around MakeSpace. After a welcome from our Director Mark Miodownik, UCL Computer Science PhD student, 3D manufacturing enthusiast and one of our former MakeSpace members Antonio Castaneda kicked off with a fantastic overview of what has been happening in 3D printing and in hackspace and maker communities over the last few years. He discussed the materials that people are using, different tools and techniques used, and new geometries, objects and behaviour they are making possible.

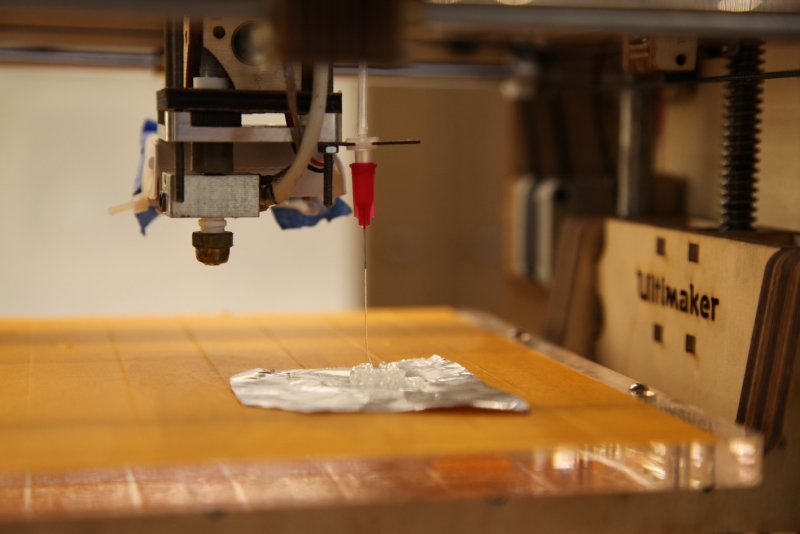

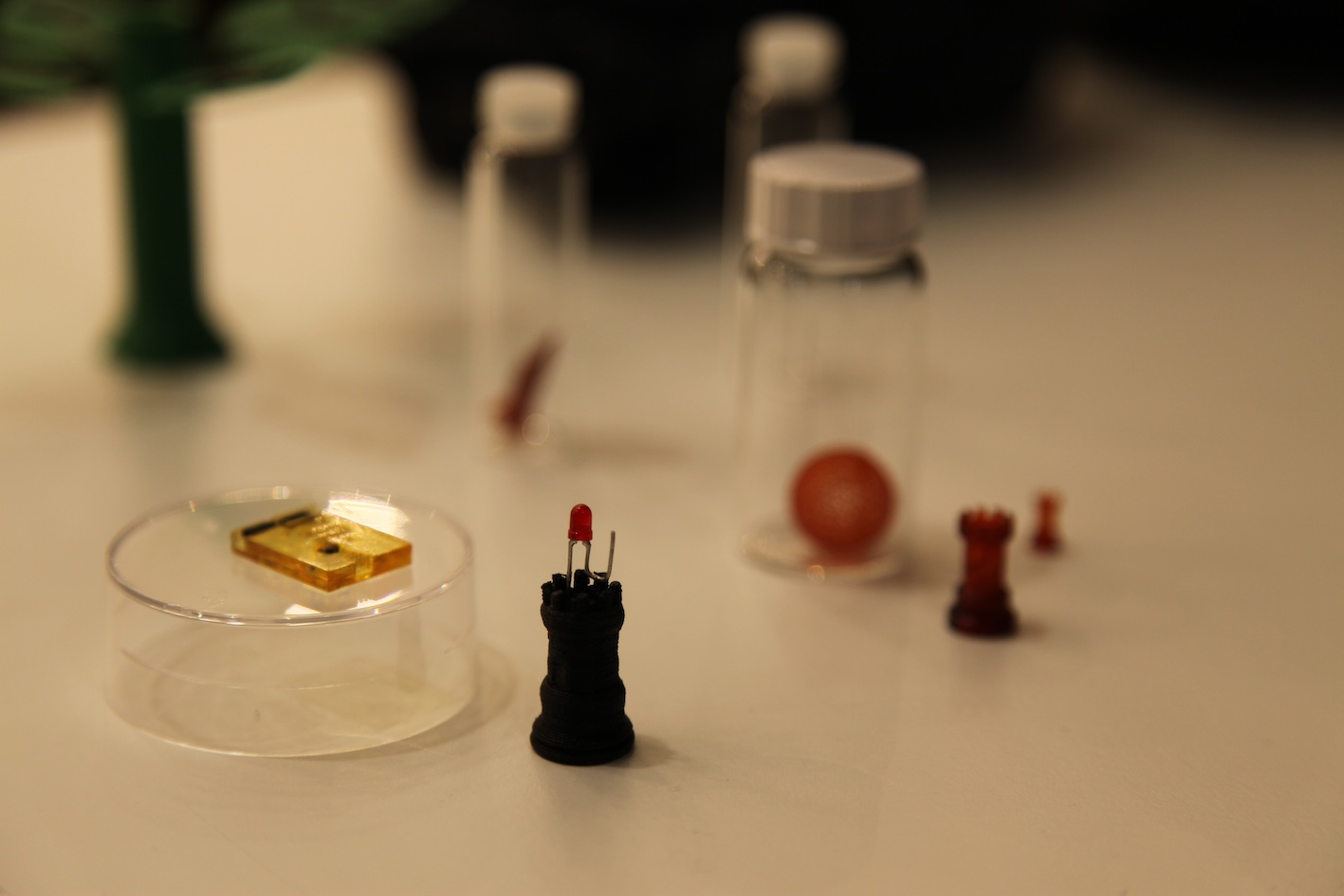

The morning session explored innovative materials and processes: Simon Leigh from Warwick University's Digital and Materials Technologies Lab discussed his work printing conductive plastics and electronic components; David Huson from UEA's Centre for Fine Print Research showed his beautiful self-glazing ceramics, faience and porcelain, and Maria Nelson and Gowishan Poologasundarampilai from Imperial presented their about their research into the printing of bioactive materials, including hybrid gelatin and silica materials, combined on the molecular level, and sol gel glasses.

After the first three presentations we had a change of pace as guests moved into the MakeSpace to chat and experiment with a couple of short and playful activites: manual extrusion of clay slip through syringes and hot glue gun extrusion of composite 'filaments' of gold leaf, thermochromic dyes, carbon black and glass ballotini. We also set participants the challenge of printing this tiny piece of chainmail before the workshop, and this allowed for an informal discussion of the different capabilities of their processes. The resulting collection nicely demonstrated the different affordances of printers and materials in use and the kinds of geometries that each technique deals with best.

After lunch the session focussed on novel designs, uses and topologies in 3D printing: Niloy Mitra from UCL Computer Science demonstrated his 'shadow art' work that is essential for the optimization of physically realisable 3D scultpures, and Richard Beckett from the Bartlett DMC discussed digitally printed masonry and 3D manufacturing at an architectural scale.

The day culminated in a discussion and demo session where participants got a chance to examine the machines, processes and objects that everyone had brought with them, and in particular to chat to the makers of the gel printer modified by the Imperial team, a new second-generation stereolithographic machine made by Pierre and Arron of Invention Works, a printer made from scratch by MakeSpace member Tom Catling, and a Form1 printer brought by Jennifer Milne.