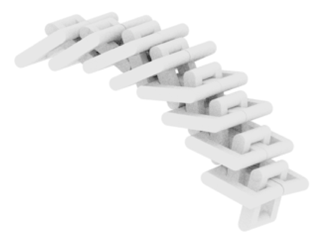

The world’s first stiffening chainmail fabric

11 July 2017

Recent years have seen a surge of interest in chainmail fabrics by the fashion industries and aerospace industries, and in nature it has been observed that certain bacteria, viruses and archaea are able to toughen up in response to environmental changes through selectively assembling a layer of “chainmail” made from interlinked proteins. Now a team of UCL researchers believe this ancient textile could play an important role in the future of materials science.

Engineering PhD student Mark Ransley, working together with Mark Miodownik and Peter Smitham, have developed a smart fabric inspired by chainmail armour and powered by shape-memory-alloys that can be stiffened electronically. They’ve also developed a modified version of a popular physics engine used to power computer games as a means of understanding the material’s behaviour and used liquid SLA 3D printing to produce the prototype. Mark Ransley explained “we hope that as the technology becomes miniaturised the fabric could be put to use in wearable assistive technology - think a smart wetsuit worn under the clothes to alleviate the need for crutches and maybe even wheelchairs”.

See a video of our smart textile in action here!

A new publication has also resulted from this work: Ransley, M.; Smitham, P.; Miodownik, M. 2017, "Active Chainmail Fabrics for Soft Robotic Applications" Smart Materials and Structures, Number 6, June 2017

This innovation formed part of the work undertaken during the EPSRC-funded Wearable Assistive Materials (WAM) project, led by Professor Nick Tyler in Civil Engineering, which brought together civil, biomedical and mechanical engineers, chemists and clinicians to develop a shape-changing smart material designed to alleviate movement-related disabilities. Find out more here. The project also received funding from the CoMPLEX PhD program and UCL’s Centre for Nature Inspired Engineering, where this work is being extended to consider the self-healing capabilities of active chainmail fabrics. We are grateful to have received funding from the EPSRC for both these projects.